When Things Get Hot!

-

The Process

High temperature coating items must be completely cleaned of all coatings, oils and contaminates. Items are then heated to high temperatures (500°plus) to ensure proper cleaning. For maximum adhesion, the item’s surface must be thoroughly blasted. After the blasting, cleaning, and heating process is completed, the item is ready for coating. Ceramic coating increases the durability and provides protection against rust and chipping. Finally, the item is ready for a

- curing treatment. The process for curing is 20 minutes of air drying, 20 minutes at 175°, immediately followed by a final curing treatment in the oven between 500° and 700°. The final process takes approximately one hour.

Benefits from High Temperature Ceramic Coating

• Reduces Heat Transfer

• Chemical Resistant

• Corrosion Resistant

• Reduces Pumping Losses -

Types of Applications

• Firearms

• Brake Parts

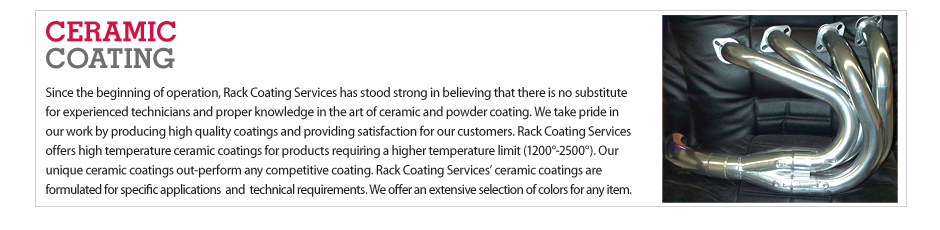

• Exhaust Systems

• High Temperature Industrial

• Pistons

• High Wear Applications

• Cylinder Heads